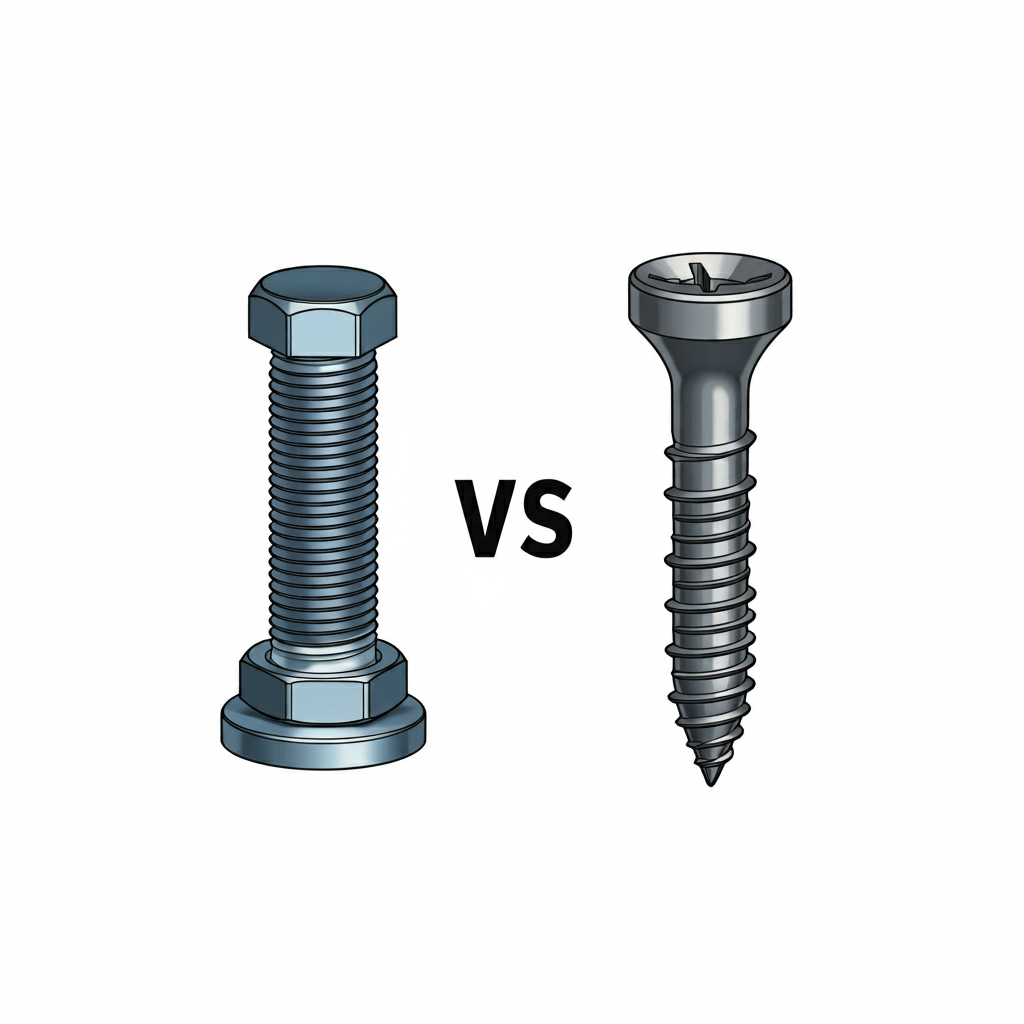

Bolts vs. Screws

Understanding the differences between bolts and screws is crucial for choosing the right fastener for your next project. Let’s dive into the details.

What is a Bolt?

A bolt is an externally threaded fastener that’s used with a nut to secure materials together. Bolts are typically paired with washers to distribute clamping force evenly and reduce material wear.

Bolts are designed for high-strength applications and are often used in construction, automotive, and heavy machinery projects. They’re generally made of durable materials like steel, stainless steel, or alloy steel to withstand high levels of stress.

What is a Screw?

A screw is an externally threaded fastener that typically creates its own threads in the material it’s driven into. Screws are designed to be used without a nut and are ideal for securing wood, metal, plastic, or other materials.

Screws come in various head types, such as Phillips, flathead, and TORX, each designed for specific applications. They are widely used in woodworking, light construction, and home improvement projects.

Differences Between Bolts and Screws

While bolts and screws may seem similar at first glance, they differ in terms of construction, load-bearing capacity, and cost. Here’s a detailed comparison:

Comparison Table

| Characteristic | Bolts | Screws |

|---|---|---|

| Fastening Method | Tightened by torquing a nut | Fastened with a screwdriver or drill |

| Threading | Usually partially threaded | Can be fully or partially threaded |

| Clamping Force | High | Low to moderate |

| Load-Bearing Strength | High | Low |

| Cost | Higher | Lower |

| Applications | Construction, automotive, heavy-duty | Woodworking, light construction, DIY |

Construction

Bolts are typically partially threaded, with a smooth shank that adds to their overall strength. The threaded part is only meant to engage the nut, which makes the bolt highly effective at clamping materials together. The unthreaded shank helps prevent shearing under heavy loads.

Screws, in contrast, can be fully or partially threaded. Fully threaded screws provide maximum grip but can sacrifice some shear strength compared to partially threaded screws.

Drive Types

Screws come in a variety of drive types, including Phillips, flathead, TORX, and square drive. This variety makes screws versatile but also requires multiple tools for different projects. Bolts usually have hex or square heads, which are tightened using a wrench or socket set.

Clamping Force

Bolts provide significantly higher clamping force compared to screws. When a nut is torqued onto a bolt, it applies a strong compressive force that holds materials together securely. This makes bolts ideal for heavy-duty applications where joint strength is critical.

Screws, on the other hand, rely on the threads cutting into the material to hold things in place. This makes them less effective for high-stress applications but perfect for lighter, precision-based tasks like attaching trim or assembling furniture.

Data Comparison: Load-Bearing Capacity

Let’s look at some load-bearing data to illustrate the difference:

- 1/4-inch Eye Bolt: 600 lbs of load capacity.

- Wood Screw (3-inch): 80-100 lbs of load capacity.

- 1/2-inch Hex Bolt: Up to 1,200 lbs, depending on material and torque.

- Drywall Screw (2-inch): 50-60 lbs, best used for non-structural applications.

Load-Bearing Strength

Bolts are far superior to screws in terms of load-bearing strength. The combination of a bolt, nut, and washer distributes pressure evenly, reducing the risk of material failure. This is why bolts are often used in structural applications like bridges, buildings, and machinery.

Screws have a lower load-bearing capacity and are better suited for projects that don’t require substantial strength. For example, screws are perfect for attaching drywall or assembling furniture but should never be used in high-stress environments.

Cost Considerations

Bolts are generally more expensive than screws. The higher cost is due to the materials used, the need for nuts and washers, and their greater strength and durability. In large construction projects, the cost of bolts can add up quickly, which is why they are reserved for critical structural elements.

Screws are more affordable and are the go-to choice for most home improvement projects. They are mass-produced and widely available, making them a cost-effective solution for everyday tasks.

When to Choose Bolts Over Screws

- Heavy-Duty Applications: Use bolts when you need maximum strength and durability, such as in load-bearing structures or machinery.

- Automotive Use: Bolts are essential for securing parts in cars, trucks, and heavy vehicles.

- Outdoor Projects: For decks and outdoor structures that need to withstand harsh weather, bolts offer superior performance.

When to Choose Screws Over Bolts

- Woodworking: Screws are ideal for cabinetry, furniture, and trim work where precision is more important than brute strength.

- Light Construction: Use screws for drywall, fencing, and other non-structural elements.

- DIY Projects: Screws are perfect for various DIY projects like building shelves, attaching brackets, or assembling small structures where you need a secure hold without the complexity of nuts and washers.

Pros and Cons of Using Bolts and Screws

Advantages of Bolts

- High Load-Bearing Capacity: Bolts can handle substantial weight and stress, making them essential for structural integrity.

- Reliability: Bolts are incredibly reliable and less likely to loosen over time, especially when used with locking nuts or washers.

- Durability: Made from high-strength materials, bolts are built to last even under extreme conditions.

Disadvantages of Bolts

- Complex Installation: Bolts require the use of nuts and often washers, which can make installation more complicated compared to screws.

- Higher Cost: Bolts and their accessories (nuts and washers) are more expensive than screws, which can increase project costs.

- Time-Consuming: Using bolts generally takes longer due to the need for additional components and tools, like wrenches or socket sets.

Advantages of Screws

- Ease of Use: Screws are easy to install using a standard screwdriver or power drill, making them ideal for quick projects.

- Cost-Effective: Screws are inexpensive and widely available, making them a practical choice for everyday tasks.

- Versatility: With various types and sizes, screws are suitable for a broad range of materials and applications.

Disadvantages of Screws

- Lower Strength: Screws are not as strong as bolts, making them unsuitable for heavy-duty applications.

- Prone to Loosening: Screws can loosen over time, especially in applications subject to vibration or movement.

- Potential for Stripping: The head of a screw can strip easily if too much torque is applied, rendering the screw useless.

Common Applications

Understanding when to use bolts versus screws can save you time, money, and frustration in the long run. Here are some common scenarios for each fastener:

Applications for Bolts

Bolts are ideal for projects that require strong, durable connections. Here are a few examples:

- Structural Construction: Bolts are used to join steel beams, wooden frames, and other load-bearing structures.

- Automotive Assembly: From engine components to frame attachments, bolts provide the strength needed in vehicles.

- Heavy Machinery: Industrial equipment often relies on bolts to keep critical parts securely in place.

- Outdoor Decking: Deck builders use bolts to secure large support beams and joists, ensuring the structure can handle heavy loads and fluctuating weather conditions.

Applications for Screws

Screws are used in a variety of projects, particularly where less strength is required but ease of installation is a priority:

- Woodworking: Screws are perfect for furniture assembly, cabinetry, and wooden trim work.

- Home Repairs: Screws are a staple for quick home fixes like attaching curtain rods, hanging picture frames, and repairing hinges.

- Drywall Installation: Drywall screws are designed to create a secure attachment without damaging the material.

- Fencing: Screws are commonly used in building fences, especially when attaching panels to posts.

Real-Life Example: Building a Wooden Deck

Let’s consider a real-life project to illustrate when to use bolts versus screws. If you’re building a wooden deck, you’ll likely use both types of fasteners:

Bolts for Structural Support

For the primary support beams and joists, bolts are the best choice. The high load-bearing capacity of bolts ensures the deck can handle the weight of people, furniture, and outdoor equipment. Bolts, when used with washers, distribute pressure evenly and prevent the wood from splitting or becoming damaged over time.

Screws for Deck Boards

For attaching the deck boards to the joists, screws are more suitable. They are easy to install, create a secure hold, and are less likely to damage the boards. Additionally, using deck screws helps prevent rust and corrosion, especially if the deck is exposed to the elements.

Data: Fastener Durability

Consider this data when choosing fasteners for a deck:

- Galvanized Bolts: Last up to 50 years with proper maintenance.

- Stainless Steel Screws: Resistant to rust and corrosion, ideal for humid or coastal environments.

- Coated Deck Screws: Designed to resist rust but may need replacement after 10-15 years.

Summary: When to Choose Each Fastener

In summary, bolts and screws each have their strengths and are best suited to different types of projects:

Choose Bolts When:

- You need maximum load-bearing strength.

- The project involves heavy-duty or structural work.

- Durability and longevity are critical factors.

Choose Screws When:

- You’re working on a project that requires precision.

- Ease of installation is a priority.

- The project is non-structural or involves lighter loads.

By understanding the key differences between bolts and screws, you can make informed decisions for your projects, ensuring safety, durability, and cost-effectiveness.